Retail shelves drive sales. But messy, empty aisles turn customers away. Restocking takes time and staff hours. What if a simple mat cut costs and kept shelves full?

Gravity mats use a slight incline and a low-friction HDPE base to move products forward on their own. That cuts labor, slashes waste, and boosts sales without power or complex parts.

If you want to save money and speed up shelf work, keep reading.

What are gravity mats?

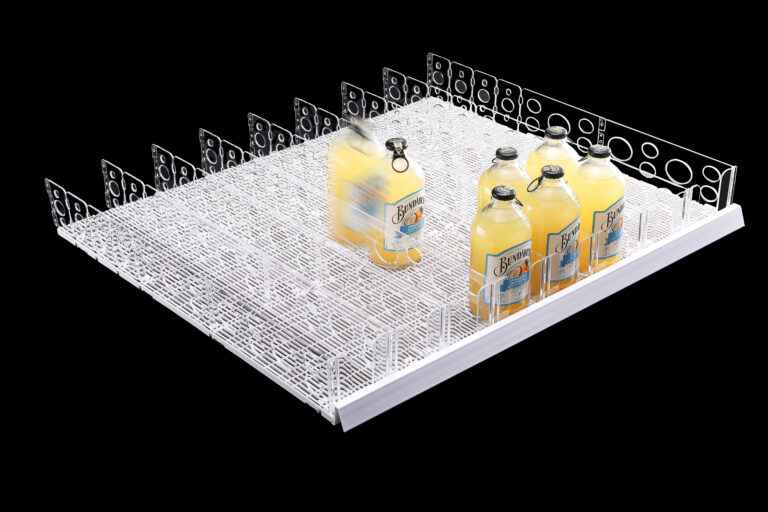

Gravity mats are plastic inserts for retail and fridge shelves. They use gravity to push bottles, cans, and boxes forward after one is taken. No springs. No motors. Just a smooth HDPE surface and a small slope.

A gravity mat sits on a shelf inclined by about 6° to 9°. As each item is removed, the one behind slides into place. Staff only refill at the back. The mat does the rest.

Key components

- HDPE base: low friction, cold-safe, food-grade

- GPPS dividers: clear lanes, easy adjust, durable

- Front stopper: holds items in place at rest

Common uses

Retailers install them in:

- Beverage aisles

- Fridge doors

- Convenience stores

- Dairy sections

They work with bottles, cans, jars, and boxed snacks.

How they differ from other systems

| Feature | Gravity Mat | Roller Track | Spring Pusher |

|---|---|---|---|

| Power needed | None | None | None |

| Moving parts | Zero | Multiple rollers | Springs |

| Cold-safe | Yes | Varies | No |

| Installation tools | None | Some brackets | Clips or screws |

| Cost per shelf | Low | Medium | High |

Gravity mats focus on simplicity. They have no moving parts. That means less to break, no energy use, and a lower price point.

Dive deeper: Gravity mats work by combining gravity with a low-friction HDPE surface. HDPE stands for high-density polyethylene. It stays smooth and flexible, even in cold sections. The shelf must tilt slightly. Most racks allow that. If not, small risers under the back edge do the trick. Once in place, staff load products at the rear. When a shopper takes an item, the next one glides forward. This removes manual facing. Staff no longer walk each aisle pulling items forward. They save time. They save steps. Over a full store, these minutes add up to hours per day.

GPPS dividers snap into slots on the mat. GPPS stands for general purpose polystyrene. It stays clear and firm, even at low temperatures. Dividers keep items in lanes. They prevent tipping and cross-mixing. Staff can adjust lane width by moving dividers. That suits cans, bottles, or boxes of different sizes.

Compared to roller tracks, gravity mats cost less. Roller tracks use wheels or bearings that can freeze or jam in cold. They need brackets and sometimes tools for install. Gravity mats drop in place. No tools, no special skills. Compared to spring pushers, mats have no springs to wear out or rust. Springs can lose tension over time, requiring upkeep. Gravity mats only need a wipe-down now and then.

In short, gravity mats are a low-tech solution with high impact. They cut labor, reduce errors, and keep shelves looking full. They suit any retailer that wants a simple, cost-effective shelf management tool.

How do mats cut shelf costs?

Shelf management costs include labor, maintenance, and lost sales. Gravity mats tackle all three. They streamline restocking, slash upkeep, and boost product visibility.

By automating product facing, gravity mats reduce staff hours. They require almost no upkeep and help sell more items by keeping inventory front and center.

Labor savings

Staff spend hours each day pulling items to the front. With gravity mats, facing is automatic. A quick back-of-shelf refill replaces hours of manual work.

Maintenance reduction

No springs or wheels to clean. No motors to power. Mats need only a light wipe with mild detergent. That cuts maintenance budgets and downtime.

Sales lift

Full, front-facing shelves attract buyers. Retail studies show a 10–15% bump in turnover when products are always at the front. That offsets the mat cost rapidly.

| Cost Factor | Traditional Method | Gravity Mat Impact |

|---|---|---|

| Labor hours | 30+ hours/week | 10 hours/week saved |

| Maintenance spend | Moderate | Minimal |

| Lost sales (gaps) | 5–10% turnover loss | Gaps eliminated |

| ROI period | N/A | 4–6 weeks |

Gravity mats start paying back within weeks. A mid-sized store with 100 shelves might spend $350 on mats. If those mats save 10 labor hours per week at $15/hour, that’s $150 saved weekly. The mats pay for themselves in under three weeks.

Dive deeper: Let’s break down labor costs. A typical grocery store employee earns $15 per hour. Facing shelves might take two hours daily. That is 10 hours per week per person per section. Multiply by three sections and one employee, and that is 30 hours weekly. At $15/hour, labor costs hit $450 each week. Gravity mats cut that time by 50–75%. Even a 50% cut saves $225 weekly. That adds up to $11,700 annually from one section alone.

Maintenance is next. Roller tracks need lubrication. Spring pushers need tension checks. Both can break and require parts. Gravity mats need only a wipe-down and occasional divider check. That might cost $5–10 monthly in cleaning supplies versus $50–100 for other systems.

Sales lift matters too. Full shelves avoid “empty” signs. Shoppers buy what they see. A 10% sales increase on $10,000 weekly sales is $1,000 more each week. That adds $52,000 annually. Even a modest 5% uplift nets $26,000.

Table of combined savings:

| Category | Annual Savings |

|---|---|

| Labor | $11,700 |

| Maintenance | $1,000 |

| Sales lift (5%) | $26,000 |

| Total | $38,700 |

Can mats lower labor expenses?

Yes. Labor is one of the biggest recurring costs in retail. Anything that saves time on repetitive tasks can lower overall spending. Gravity mats directly reduce the need for shelf-facing labor.

Gravity mats cut down the time workers spend repositioning products by making products automatically slide forward after one is picked. That reduces storewide labor hours by a significant margin.

What causes shelf labor waste?

In most stores, staff face the same product displays multiple times a day. That includes pulling bottles forward, cleaning shelf gaps, adjusting positions, and ensuring the front row stays full. Without a system in place, this gets repeated shift after shift.

How gravity mats help

With gravity mats, all that facing happens automatically. Workers simply load from the back. There’s no more need to pull each product forward manually.

| Shelf Task | Without Mats | With Gravity Mats |

|---|---|---|

| Manual product facing | Required | Not needed |

| Shelf gap adjustment | Frequent | Rare |

| Cleaning repositioning | Often | Reduced |

| Restocking training | Detailed | Basic |

Labor time breakdown

Assume each aisle takes 1 hour per day to maintain manually. If gravity mats save 40 minutes per aisle, that’s 4 hours saved across 6 aisles per day. At $15/hour, that’s $60 daily. In a 30-day month, that’s $1,800 saved.

The long-term view

| Time Period | Hours Saved | Cost Savings |

|---|---|---|

| 1 Week | 20+ hrs | $300 |

| 1 Month | 80+ hrs | $1,200 |

| 1 Year | 1,000+ hrs | $15,000+ |

Lower labor needs also allow leaner shift planning, less burnout, and fewer mistakes under time pressure.

What factors affect mat ROI?

Return on investment (ROI) depends on multiple elements—store size, product turnover, shelf type, labor costs, and maintenance needs.

The ROI of gravity mats is influenced by labor time saved, boost in product visibility, installation ease, and the frequency of restocking. In many retail settings, mats pay for themselves in weeks.

Key ROI drivers

- Store traffic: high footfall = frequent restocking = more benefit

- Product type: fast-moving items gain more from auto-facing

- Shelf angle compatibility: optimal incline ensures reliable sliding

- Staff wage levels: higher wages = faster ROI through labor cuts

ROI timeline estimate

| Store Size | Labor Saved (hrs/week) | ROI Period |

|---|---|---|

| Small | 5–10 | 6–8 weeks |

| Medium | 10–20 | 3–5 weeks |

| Large | 30+ | 2–3 weeks |

Additional gains

Don’t forget less obvious savings: reduced staff fatigue, faster training, better shelf cleanliness, and fewer lost sales due to empty spots.

Improving ROI further

You can push ROI even faster by:

- Adding mats only to high-turnover areas first

- Training staff to load efficiently from the back

- Pairing with clear signage for better shopper flow

Gravity mats are a low-cost investment that solve multiple problems at once. The bigger your stor

Conclusion

Gravity mats are not just a clever shelf trick—they’re a real business tool. They save labor. They reduce shelf maintenance. They improve the way your products look to customers. From beverage aisles to fridge units, from chain stores to local markets, they simplify one of the most time-consuming tasks in retail: restocking.

If your store deals with fast-moving goods and daily shelf resets, gravity mats may be one of the most affordable upgrades you can make. They install in minutes. They require no electricity. And they start saving money from day one. Whether you’re a supermarket manager, a store designer, or a retail equipment distributor, these mats could be the most cost-effective change to your shelf management strategy this year.

Thank you for reading. If you’re ready to take your shelves from “good enough” to efficient and clean—gravity might just be the force you’ve been missing.