In busy retail stores, restocking shelves takes up more time than most people realize. Workers walk back and forth, rearranging items and pulling products forward so shelves always look full. But what if the shelf could do that job itself?

Gravity shelf sliding mats make restocking faster and easier by using sloped shelves and smooth surfaces to push products forward automatically. No power, no springs—just smart design.

These mats are already used in beverage displays, cold food sections, and convenience store aisles. They help retailers save time, reduce mess, and improve how products look. Let’s take a closer look.

What are gravity shelf sliding mats?

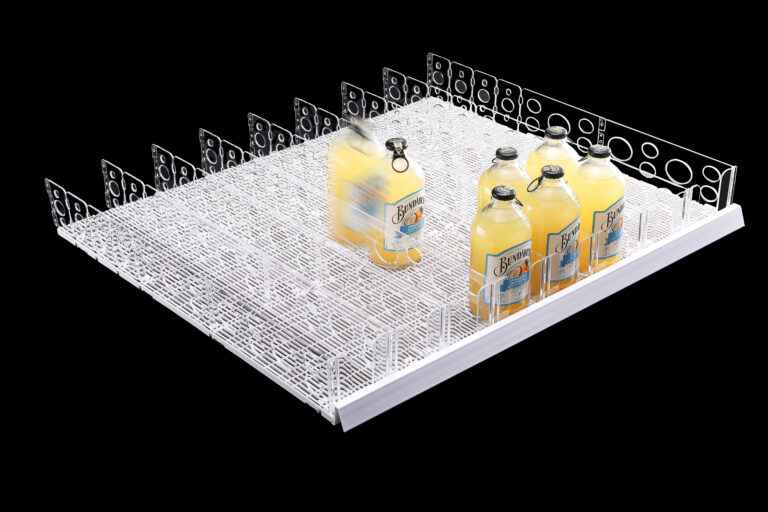

Gravity sliding mats are simple shelf tools made from plastic. They sit on a sloped shelf, using gravity to move products to the front as they are picked up.

Gravity shelf mats are made of smooth plastic with built-in gliding features, helping bottles and cans move forward without extra effort.

How do gravity mats work?

Each mat uses a slightly slanted shelf surface—usually around 6° to 9°. When one item is removed, the others naturally slide forward. This reduces the need for manual facing.

Where are they used?

These mats are popular in:

- Beverage aisles

- Commercial refrigerators

- Cold food displays

- Drugstores

- Convenience stores

They work best with bottles, cans, boxed drinks, and packaged food.

Key product components

| Part | Material | Function |

|---|---|---|

| Sliding mat | HDPE | Friction-reducing product base |

| Dividers | GPPS | Keep products in aligned channels |

| Front stopper | ABS | Stops bottles from falling forward |

How do sliding mats simplify restocking?

Stocking shelves takes time. It often means reaching to the back and pulling items forward. That’s called “facing,” and it’s repeated over and over every day.

With sliding mats, the shelf faces itself. Products stay in order and at the front, which saves workers time and effort.

Why it matters

Retailers pay staff by the hour. Any task that takes time, like shelf maintenance, adds cost. Sliding mats help cut that cost by automating part of the work.

Time savings in real use

Let’s look at how sliding mats reduce time spent per shelf:

| Task | Without Mat | With Mat | Time Saved |

|---|---|---|---|

| Daily beverage facing | 6 mins | 1 min | 83% |

| Shelf wiping and sorting | 4 mins | 1.5 min | 62% |

| Product restocking | 8 mins | 4 mins | 50% |

This adds up quickly across a store with 100+ shelves.

Less training, fewer mistakes

Sliding mats reduce human error. No need to train staff on exact product alignment. Just load, and the mat takes care of the rest.

Why choose HDPE for sliding mats?

Not all plastics are the same. HDPE (High-Density Polyethylene) is chosen for its balance of strength, safety, and cold resistance.

HDPE makes mats more durable, easier to clean, and safer for cold environments where traditional plastic might crack or warp.

Benefits of HDPE

- Works in cold storage down to -10°C

- Non-toxic and food-safe

- Resists mold and moisture

- Strong yet flexible

Comparison with other plastics

| Material | Cold Resistance | Flexibility | Food Safe | Cost |

|---|---|---|---|---|

| HDPE | Excellent | High | Yes | $$ |

| GPPS | Poor | Low | No | $ |

| ABS | Moderate | Medium | No | $$$ |

HDPE also holds its shape better over time, which means fewer replacements and more consistent results.

How does shelf angle impact sliding?

Gravity mats rely on sloped shelves. The angle determines how smoothly products move.

The best results come from a 6° to 9° incline, allowing steady forward movement without sudden rolling or tipping.

What if shelves are flat?

If shelves aren’t angled, gravity won’t help. Mats will not work properly. But this can be fixed with spacers or risers added to the back edge of the shelf.

Ideal shelf setup

| Angle | Effect |

|---|---|

| 0° | No movement |

| 3° | Some sliding, not consistent |

| 6° | Optimal for most product types |

| 9° | Best for heavier bottles |

| >9° | Risk of products tipping forward |

A slight incline is usually enough to activate the sliding feature without creating a mess.

Do sliding mats reduce labor costs?

Labor is one of the biggest store expenses. Restocking, shelf-facing, and cleaning take hours. Sliding mats help stores do more with fewer people.

By speeding up shelf maintenance, mats reduce the hours staff need to spend on routine tasks.

How costs go down

Let’s break it down in dollar terms:

| Store Size | Staff Time Saved/Week | Hourly Rate | Weekly Savings |

|---|---|---|---|

| Small | 10 hours | $15 | $150 |

| Medium | 20 hours | $15 | $300 |

| Large | 30+ hours | $15 | $450+ |

This doesn’t even count fewer training hours, lower error rates, or improved efficiency during peak hours.

Can mats improve product visibility?

Yes. Products at the front are easier to see, touch, and buy. Shoppers don’t like reaching to the back or digging through clutter.

Gravity mats keep products neatly front-facing at all times. That means better visibility, cleaner presentation, and stronger sales.

Why front-facing matters

Most shoppers only look at the first few rows. If your best-sellers are hidden in the back, they won’t move.

Better layout = better impressions

Gravity mats ensure:

- No gaps on shelves

- Better brand exposure

- Easier price tag visibility

Are mats safe for refrigerated shelves?

Cold display areas pose challenges for materials. Moisture builds up. Temperature shifts. Some plastics break or deform. Not HDPE.

HDPE gravity mats are ideal for cold aisles, with anti-slip, non-brittle surfaces that won’t crack under pressure.

Cold shelf challenges

| Problem | Solution via HDPE Mat |

|---|---|

| Frost buildup | Non-porous material resists it |

| Product sticking | Smooth base keeps items gliding |

| Plastic warping | HDPE keeps its shape |

These mats are also easy to remove for quick shelf cleaning and maintenance.

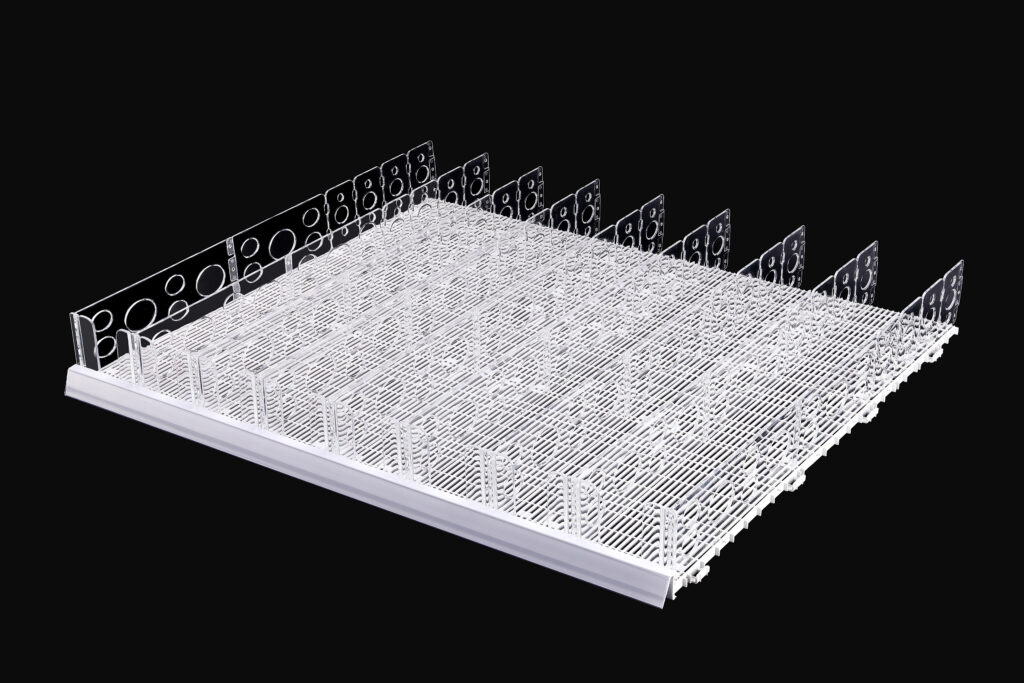

How easy is sliding mat installation?

You don’t need a technician to install these. Store teams can install them in minutes—no tools required.

Sliding mats are plug-and-play. Just drop them in place, adjust dividers, and you’re ready to stock.

Installation steps

- Set shelf angle (if needed)

- Place mat on shelf

- Adjust width dividers

- Load products

Time required

| Shelf Count | Time w/o Mat | Time w/ Mat |

|---|---|---|

| 1 shelf | 20 mins | 5 mins |

| 10 shelves | 3.5 hours | 1 hour |

| 50 shelves | 15 hours | 4 hours |

Can mats adjust for different product sizes?

Not all bottles or boxes are the same. That’s why Novaday mats are built with flexible width settings and optional dividers.

Each mat can be set to fit different product widths. From 250ml cans to 1.5L bottles, everything stays in line.

Three-stage adjustable lanes

| Stage | Product Fit |

|---|---|

| Narrow | Energy drinks, cans |

| Medium | Standard bottles |

| Wide | Large PET bottles |

Divider features

- Removable and repositionable

- Transparent for product visibility

- Keeps items from tipping sideways

Is sliding mat ROI worth it?

Every investment should pay for itself. Gravity mats don’t just save money. They also improve shelf layout, reduce restocking time, and boost customer satisfaction.

Most stores recover their cost in just a few months through labor savings and higher sales.

Return on investment example

| Cost Item | Amount |

|---|---|

| Mat system | $3.50 per mat |

| Labor saved | 10+ hours/week |

| ROI period | ~4-6 weeks |

Who benefits most from sliding mats?

Gravity mats help many types of stores. Some use them to improve cold shelves. Others use them to boost restocking speed.

If your business uses shelves and sells high-turnover products, sliding mats can save you time and money.

Perfect for:

- Grocery stores

- Beverage chains

- Small convenience stores

- Dairy and cold storage sections

- Refrigerated displays

Conclusion

Gravity shelf sliding mats offer a simple, powerful way to reduce restocking time and improve shelf appearance. They use nothing more than gravity and smooth design to move products forward, cut labor costs, and boost efficiency. Whether you’re running a supermarket, outfitting a fridge aisle, or setting up a convenience store, adding HDPE sliding mats can change how your team works—one shelf at a time.