In a retail environment, plastic sliding mats take a beating. They hold products, face daily traffic, deal with cold, and get wiped down constantly. One bad material choice can lead to cracks, warping, or product jams. That’s why understanding the materials behind sliding mats matters more than most store managers think.

The durability of plastic sliding mats depends on the base material like HDPE and accessory materials like GPPS. These determine whether mats stay strong, safe, and functional in real-world shelf conditions.

Choosing the right mat isn’t just about fit. It’s about lasting performance under pressure.

What materials are used in sliding mats?

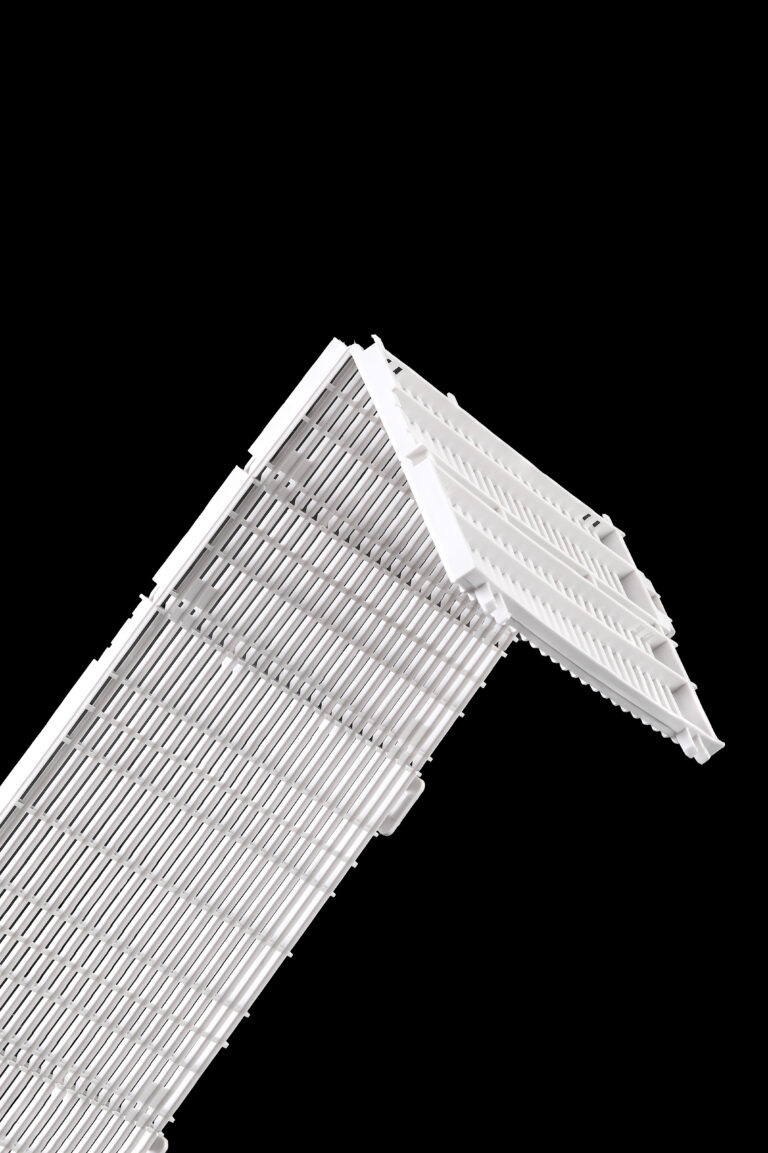

Sliding mats are made from a few specific plastics, each chosen for their strength and resistance. The three main components are the base mat, the dividers, and the stopper.

Most sliding mats use HDPE for the base, GPPS for the dividers, and ABS or PET for structural parts like stoppers.

Common Materials and Their Properties

| Component | Material | Key Properties |

|---|---|---|

| Base Mat | HDPE | High strength, flexible, cold-resistant |

| Divider Walls | GPPS | Clear, rigid, easy to mold and adjust |

| Front Stoppers | ABS | Tough, durable, holds shape under impact |

How durable is HDPE in cold use?

HDPE stays flexible down to –10°C and won’t crack under cold stress.

Cold conditions can ruin cheaper plastics. They go brittle. HDPE doesn’t. It bends instead of snapping. This is why it’s often used in freezer-rated shelving systems.

HDPE in Freezer Tests

| Temperature | HDPE Behavior |

|---|---|

| Room Temp (20°C) | Normal Flexibility |

| 0°C | No Cracking |

| –10°C | Stable, Safe |

| –20°C | Slightly Stiffer |

For beverage aisles, dairy zones, or deep freezers, HDPE performs every time.

Can GPPS dividers handle daily wear?

GPPS dividers hold up well in shelf applications, but they are less flexible than HDPE.

They won’t break under normal use. But heavy impact or bending can crack them. Luckily, their design purpose is only to separate—not carry load.

Pros and Cons of GPPS in Dividers

| Feature | GPPS Performance |

|---|---|

| Clarity | Excellent |

| Rigidity | High |

| Flexibility | Low |

| Impact Resistance | Moderate |

As long as they’re installed and used properly, GPPS dividers last for years.

Do sliding mats resist cracking?

Yes. When made from HDPE, mats resist stress fractures caused by flexing, cold, and repeated use.

ABS and PET stopper parts also resist breakage from bottle impacts or cleaning tools.

Stress Resistance Table

| Material | Cracking Risk | Notes |

|---|---|---|

| HDPE | Very Low | Ideal for high-use shelves |

| GPPS | Moderate | Avoid direct force |

| ABS | Low | Used for structural ends |

With proper handling, cracking issues are rare in sliding mats built with the right specs.

How do mats perform in freezers?

HDPE mats and GPPS dividers are cold-safe for commercial fridge and freezer use.

Freezers create condensation, frost, and temperature swings. Bad materials buckle. Good ones keep their form.

Freezer-Ready?

| Condition | HDPE | GPPS |

|---|---|---|

| Condensation | Yes | Yes |

| Frost buildup | Yes | Yes |

| Sudden temp drops | Yes | Fair |

Freezer performance depends not just on cold rating—but moisture and load handling too.

Can mats hold heavy product loads?

Yes. Sliding mats made with thick HDPE can hold up to 20 kg per lane.

The key is thickness and base design. Reinforced ribs and wider dividers spread weight better.

Weight Capacity Breakdown

| Product Type | Mat Lane Load Capacity |

|---|---|

| 500ml bottles | 10–12 kg |

| 1.5L PET bottles | 15–18 kg |

| Mixed canned goods | Up to 20 kg |

For very heavy products, retailers should use mats with denser base material and fewer dividers.

Do sliding mats warp over time?

Only poorly made mats warp. HDPE resists long-term compression and temperature damage.

Shelf systems that use thin, soft, or non-HDPE mats tend to deform. Good mats hold shape after years of use.

Warping Resistance

| Cause of Warping | HDPE Performance |

|---|---|

| Product weight | Very resistant |

| Repeated cleaning | No effect |

| UV light | Minor fade only |

As long as the mat base is properly manufactured, warping will not be an issue in standard conditions.

How often should mats be replaced?

Most HDPE-based mats last 3–5 years depending on use.

Dividers may wear quicker, especially if re-adjusted frequently. But full replacement cycles are rare.

Replacement Cycles

| Component | Avg. Lifespan |

|---|---|

| HDPE base mat | 3–5 years |

| GPPS divider | 2–3 years |

| Stopper parts | 3–5 years |

Regular inspections and cleaning extend shelf life.

Are sliding mats resistant to moisture?

Yes. HDPE and GPPS do not absorb water.

Mats stay dry and safe even when exposed to condensation or liquid spills. This keeps bacteria growth low and food-safe compliance high.

Water Resistance Table

| Material | Water Absorption | Mold Risk | Cleaning Ease |

|---|---|---|---|

| HDPE | None | Very Low | Easy Wipe |

| GPPS | None | Very Low | Easy Wipe |

This also means the mats are safe for use near produce, dairy, and drinks.

What makes a mat material food-safe?

Materials must be FDA or EU compliant, non-toxic, and non-porous.

HDPE and GPPS meet food-contact safety standards and don’t leach chemicals.

Safety Checklist

| Property | Requirement Met? |

|---|---|

| BPA-Free | Yes |

| Non-leaching | Yes |

| Easy to sanitize | Yes |

| Cold-safe | Yes |

Sliding mats made from these materials meet the safety needs of modern retail.

Conclusion

Durability isn’t just about lasting longer—it’s about keeping performance high day after day. HDPE and GPPS offer the right mix of strength, safety, and cost for plastic sliding mats. They handle weight, resist cold, shrug off cleaning, and meet food safety standards. When used correctly, these materials help retailers run smoother shelves for years—no cracks, no warping, no problem.