WHY PLASTIC PET SHELF DIVIDERS ARE A SMART CHOICE FOR MODERN RETAIL DISPLAYS

Need reliable, clean-looking, and durable shelf dividers for your store? PET plastic shelf dividers could be the best decision you make this year.

Let’s dive in.

WHAT EXACTLY ARE PET SHELF DIVIDERS?

PET stands for Polyethylene Terephthalate — a lightweight, transparent plastic best known for its use in packaging and beverage bottles. But it’s also making waves in retail merchandising as a superior material for shelf dividers.

These dividers are installed directly on store shelves to:

- Create clean boundaries between SKUs

- Improve product visibility

- Enhance customer experience

In organized stores, products sell better. PET dividers help make that happen.

WHY RETAILERS ARE SWITCHING TO PET

PET shelf dividers aren’t just trendy — they’re functional, durable, and built for real-world use. Here’s why retailers are making the switch:

1. Crystal-Clear Visibility

PET offers long-lasting transparency. Unlike materials that yellow over time, PET stays crystal clear — keeping your display visually sharp and your products front and center.

2. Tough but Lightweight

PET is strong enough to endure daily use yet light enough for fast installations and reconfigurations. This combo reduces labor time and prevents shelf damage.

3. Resistant to Moisture and Cleaning Agents

From beverage aisles to cosmetics counters, PET handles humidity and harsh cleaning agents without warping or clouding.

4. 100% Recyclable

PET is fully recyclable, aligning your operations with sustainability goals and modern consumer expectations.

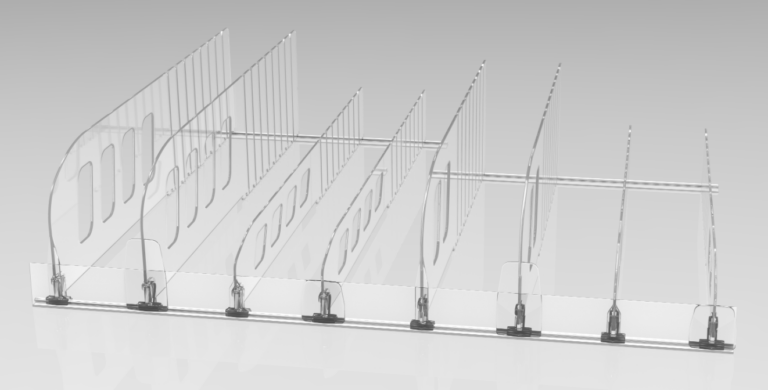

HOW PET SHELF DIVIDERS ARE MADE: THE INJECTION MOLDING ADVANTAGE

Behind every shelf divider is a carefully controlled manufacturing process. Novaday uses plastic injection molding, the gold standard for precision and durability.

STEP 1: MOLD DESIGN

Everything starts with the mold. Our in-house R\&D team designs precise molds tailored to your shelf system and product layout.

- Custom sizes

- Unique edge shapes and locking mechanisms

- OEM/ODM services for brand-specific designs

We control the entire mold-making process, ensuring fast development and consistent results.

STEP 2: PET MATERIAL LOADING

PET pellets are dried to remove moisture (which prevents air bubbles) and then loaded into our injection machines.

STEP 3: INJECTION AND COOLING

The plastic is melted and injected into the mold under high pressure, then rapidly cooled to solidify.

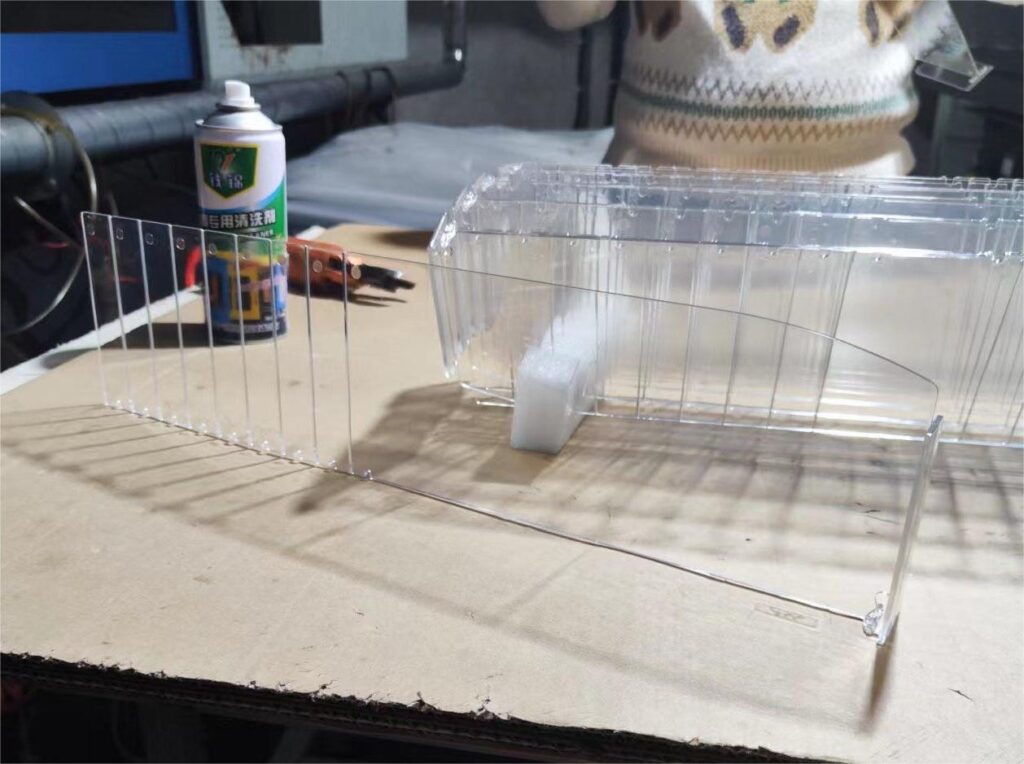

STEP 4: EJECTION AND FINISHING

Each divider is automatically released from the mold, trimmed, polished, and quality-checked for clarity, shape, and fit.

WHY INJECTION MOLDING BEATS OTHER METHODS

Compared to extrusion or thermoforming, injection molding produces:

- Cleaner edges

- Tighter tolerances

- More complex shapes

- Greater durability

| Feature | Injection Molding | Thermoforming | Extrusion |

|---|---|---|---|

| Precision | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐ |

| Surface Finish | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐ |

| Structural Strength | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐ |

| Customization | ⭐⭐⭐⭐ | ⭐⭐ | ⭐ |

| Branding Potential | High | Limited | Very Low |

That’s why we focus exclusively on PET injection at Novaday — it’s simply the best method for quality and scale.

WHERE PET DIVIDERS ARE USED — AND WHY THEY WORK

Supermarkets

Keep chilled and ambient categories tidy — from snacks to dairy to beverages.

Pharmacies and Beauty Chains

PET’s clarity enhances visibility for small items like skincare, supplements, and makeup.

Convenience Stores

Tight shelf space? PET dividers help maximize it while keeping everything aligned.

Consumer Electronics

Organize cables, accessories, and gadgets in high-traffic displays with confidence.

WHY CHOOSE NOVADAY FOR PET SHELF DIVIDERS?

We’re not just a supplier. We’re a full-service manufacturer that controls every step of the process — from tooling to delivery.

- ✅ PET injection molding specialists

- ✅ In-house mold development and engineering

- ✅ Strict quality control for each batch

- ✅ Fast customization and turnaround

- ✅ Global reach: Europe, Australia, North America, and South America

We understand what retailers and distributors need: dependable quality, fast response times, and tailored solutions.

💡 Why settle for generic when you can go custom — with precision PET molding?

At Novaday, PET isn’t just a material — it’s our specialty. From precision mold development to mass production of PET shelf dividers, everything happens under one roof. No middlemen. No delays. Just factory-direct control and expertise you can count on.

✔ In-house PET injection mold design

✔ Tailored product development (OEM/ODM)

✔ Fast, responsive service

✔ Export-ready for Europe, North America & Australia

If you’re looking for durable, cost-efficient, and retail-ready PET shelf dividers, this is the sign to get in touch.

📩 Reach out to our team today to get a quote, see samples, or request a custom solution.

📚 Ask for our latest shelf management catalog — and take the first step toward better retail display performance.

Novaday — where PET precision meets shelf innovation.

📌 Hashtags

#PETshelfdividers #InjectionMolding #RetailDisplay #NovadayFactory #CustomRetailSolutions #PlasticManufacturing #StoreEquipmentSupplier