Introduction

Imagine walking into a store where every product is neatly aligned, effortlessly gliding forward as items are taken, making shopping seamless. No awkward gaps, no messy shelves—just a pristine, organized display that subtly guides customers toward making a purchase. This isn’t retail magic; it’s the power of shelf roller tracks—one of the most underrated yet indispensable tools in modern merchandising.

Retailers today face a hidden battle: capturing attention in an era of shrinking patience. Shoppers demand convenience, speed, and visually appealing displays, and those who fail to deliver risk losing sales to competitors who do. A cluttered, misaligned shelf can send the wrong message, creating hesitation instead of encouraging impulse buys. That’s where shelf roller tracks revolutionize the game. Designed to maintain perfect shelf alignment while ensuring effortless product movement, these simple yet brilliant systems streamline stocking, enhance product visibility, and even reduce waste.

But why are major retailers and supermarkets rapidly adopting these systems? More importantly, how can they boost efficiency, increase sales, and improve the overall shopping experience? Whether you’re a retail store owner, a supermarket supplier, or a shopfitting expert, understanding the role of shelf roller tracks could be the key to unlocking a more profitable and visually appealing store layout. Let’s dive in.

What is a Shelf Roller Track, and Why Do Retailers Use It?

1. Understanding Shelf Roller Tracks: The Basics

What is a Shelf Roller Track?

Ever noticed how certain products on store shelves always seem perfectly aligned, effortlessly rolling forward when one is removed? That’s the silent efficiency of a shelf roller track at work.

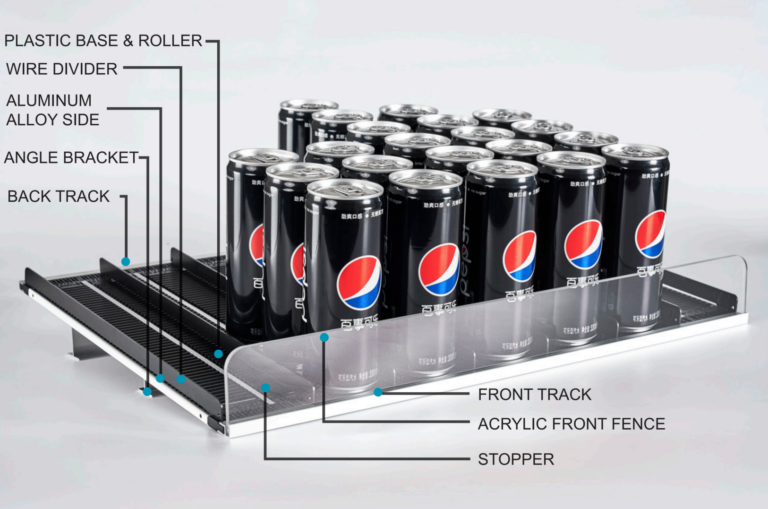

This innovative system consists of a low-friction track designed to facilitate the smooth movement of items. Whether it’s bottled beverages, packaged snacks, or pharmaceuticals, these tracks eliminate the need for constant shelf rearrangement, ensuring that the next item always moves into prime visibility.

How Do Shelf Roller Tracks Work?

Here’s the secret: gravity and precision engineering.

The system features roller-based channels that use a gentle slope, allowing items to glide forward naturally. Unlike static shelving, where products remain fixed until manually adjusted, this system continuously feeds the front of the display, keeping shelves looking full and inviting.

Materials and Construction

Not all shelf organizers are created equal. Durability and efficiency depend on the material used.

Most high-performance roller tracks are crafted from PET plastic, renowned for its strength, flexibility, and eco-friendliness. Others incorporate metal or reinforced polymers for added sturdiness, particularly in high-traffic retail settings.

2. The Key Benefits of Using Shelf Roller Tracks

Improved Product Organization

Disorganized shelves? That’s a thing of the past.

By automatically aligning products, this system prevents cluttered displays and misplaced items. Customers see exactly what’s available at a glance—eliminating the frustration of hidden products shoved to the back.

Increased Sales and Impulse Purchases

Retail psychology is clear: the easier it is to grab, the more likely customers will buy.

A seamless display experience encourages spontaneous purchases. A well-stocked, visually appealing shelf creates a sense of abundance, making shoppers feel more inclined to pick up additional items.

Reduced Restocking Time

Time is money—especially in retail.

Instead of manually front-facing every product, store employees can focus on other essential tasks. The gravity-fed system ensures that as one item is removed, the next one takes its place, cutting down on labor costs and improving operational efficiency.

3. Where Are Shelf Roller Tracks Used?

Supermarkets and Grocery Stores

Ever reached for a soda and found the front row magically refilled? That’s the impact of roller shelving in supermarkets.

Grocery retailers use these tracks extensively in beverage aisles, dairy sections, and snack displays. By keeping high-demand products readily available, they enhance customer satisfaction while boosting sales.

Convenience Stores and Gas Stations

In fast-paced environments, speed and accessibility are non-negotiable.

These stores benefit immensely from roller tracks, particularly for grab-and-go items like energy drinks, candy bars, and packaged sandwiches. When products stay front and center, shoppers make quicker purchasing decisions.

Pharmacies and Health Stores

Precision matters in pharmaceutical retail.

Roller tracks ensure that medicines, vitamins, and supplements remain properly organized, reducing confusion and minimizing the risk of expired stock sitting unnoticed at the back of a shelf.

4. How Shelf Roller Tracks Enhance Inventory Management

First-In-First-Out (FIFO) Stock Rotation

Expired products? Retailers can’t afford that.

Shelf roller systems naturally follow the FIFO principle, ensuring that older products are sold first. This is particularly crucial for perishable goods and time-sensitive inventory, reducing waste and protecting profit margins.

Preventing Overstock and Stockouts

Stocking errors are a retail nightmare.

With clear visibility into shelf availability, employees can instantly spot when inventory is running low—minimizing out-of-stock situations and preventing excessive ordering of unnecessary items.

Minimizing Product Damage

Ever seen a stack of crushed cereal boxes? Improper shelving can cost businesses thousands in damaged goods.

By guiding product movement smoothly, roller tracks reduce impact damage, ensuring that fragile items stay intact from stocking to checkout.

5. Customization and Design Options

Adjustable Track Widths and Configurations

Not all stores are the same—so why should their shelving be?

Retailers can customize roller track sizes, widths, and angles to accommodate different product types. Whether it’s narrow tubes of cosmetics or large bottles of detergent, tailored solutions ensure a perfect fit.

Integration with Electronic Shelf Labels

Smart retail is the future.

Many modern roller track systems are designed to seamlessly integrate with electronic shelf labels (ESLs), ensuring that pricing remains accurate and promotions are automatically updated.

Branding and Aesthetic Enhancements

Store aesthetics aren’t just about function—they impact the customer experience.

Custom color-coded tracks, branded dividers, and sleek finishes help retailers create a polished and professional look that enhances visual appeal and brand consistency.

Stay tuned for the next sections, where we’ll dive into installation guides, ROI breakdowns, and cutting-edge innovations shaping the future of retail shelving!

6. Installation and Maintenance Guide

How to Install Shelf Roller Tracks

Setting up a new shelving system? It’s easier than you think.

Most roller track solutions come in modular designs, making installation quick and hassle-free. Here’s how retailers can get them up and running:

- Measure the Shelf Space – Ensure the width and depth match the intended track system.

- Secure the Base – Some models require adhesive strips, while others snap into pre-existing shelving units.

- Adjust the Slope – The slight incline ensures smooth product movement.

- Test the Flow – Place a few items to check alignment and movement before fully stocking the shelf.

Maintenance Tips for Longevity

Want to keep your shelving running smoothly for years? A little upkeep goes a long way.

- Regular Cleaning: Dust and debris can slow down product movement. A quick wipe-down prevents buildup.

- Check for Wear: Over time, heavy usage can lead to minor misalignments—adjust as needed.

- Lubricate When Necessary: If rollers become stiff, a small amount of non-greasy lubricant restores their movement.

Troubleshooting Common Problems

Even the best systems can run into issues. Here’s how to fix common problems in minutes:

- Products Aren’t Moving? Check for blockages or adjust the incline for better gravity flow.

- Uneven Rolling? Ensure that the track is level and not obstructed.

- Shelf Misalignment? Reset the base and secure it properly for stability.

7. Cost vs. Return on Investment (ROI)

How Much Do Shelf Roller Tracks Cost?

Thinking about upgrading your shelving? Let’s talk numbers.

The cost of a roller track system depends on factors like material, size, and customization. Prices generally range from:

- Basic plastic tracks: Budget-friendly, ideal for small-scale stores.

- High-end PET or metal tracks: More durable, suited for high-traffic retail environments.

Long-Term Savings for Retailers

Here’s why investing in better shelving pays off in the long run:

- Faster Restocking: Employees spend less time organizing, allowing them to focus on customer service.

- Fewer Expired Products: FIFO stock rotation reduces waste.

- Higher Sales: Customers buy more when products are easily accessible and well-displayed.

Case Study: Retailers Who Boosted Profits with Roller Tracks

Need proof? Real businesses are seeing real results.

- A major supermarket chain reduced restocking time by 40%.

- A leading pharmacy retailer lowered expired stock losses by 25%.

- A convenience store saw a 15% increase in impulse purchases due to better product visibility.

8. Trends and Innovations in Shelf Roller Tracks

Smart Shelf Roller Tracks with IoT Integration

Welcome to the future of retail.

Modern roller tracks are now equipped with smart sensors that monitor inventory levels in real time. This technology enables:

- Automated restocking alerts to prevent product shortages.

- Data-driven insights to optimize product placement.

Sustainable and Eco-Friendly Roller Tracks

Retailers are making the switch to greener solutions.

- Recycled PET materials are replacing traditional plastic.

- Biodegradable options are emerging for eco-conscious stores.

AI-Powered Shelf Management

Artificial Intelligence is revolutionizing product placement.

By analyzing customer movement patterns, AI systems can:

- Adjust shelving layouts for optimal sales performance.

- Identify slow-moving products and suggest better positioning.

9. How to Choose the Right Shelf Roller Track for Your Business

Factors to Consider Before Buying

Not sure which system is best? Ask these key questions:

- What type of products are being displayed?

- Does the track need to fit existing shelving?

- Is branding or customization important?

Comparing Different Manufacturers

With so many options, choosing a trusted supplier is critical.

- Look for durability: High-quality materials ensure longevity.

- Check for customer reviews: Other retailers’ experiences speak volumes.

- Evaluate support services: Installation guidance and warranty policies matter.

OEM and ODM Solutions for Retailers

Looking for a custom solution? Some manufacturers offer bespoke designs to match specific needs.

OEM and ODM solutions allow businesses to:

- Create unique brand-aligned shelf systems.

- Incorporate specialized track widths and angles.

- Develop private-label retail displays for exclusive products.

10. Conclusion: Are Shelf Roller Tracks Right for Your Store?

The right shelving system can make or break a retail space.

Shelf roller tracks offer efficiency, organization, and increased sales potential. From supermarkets to pharmacies, retailers worldwide are investing in this game-changing solution.

Looking to optimize your store’s layout? Now is the time to upgrade.