Introduction: The Foundation of Efficient Shelf Roller Track Systems

When it comes to optimizing retail shelf performance, shelf roller track systems play a crucial role. These systems streamline product movement, enhance organization, and ensure seamless replenishment. But have you ever wondered what materials go into making them durable and effective?

The right choice of materials can significantly impact longevity, cost, and functionality. Some are lightweight and budget-friendly, while others prioritize durability and high load-bearing capacity. Understanding these differences helps businesses make informed decisions that align with operational needs.

In this guide, we’ll break down the most common materials used in roller track construction, covering their advantages, drawbacks, and ideal applications. Whether you’re a supermarket manager, a retail designer, or a distributor, this deep dive will equip you with the insights needed to choose the best solution for your store fixtures.

The Role of Materials in Shelf Roller Track Systems

Shelf roller track systems are the backbone of retail efficiency. But what makes them durable, cost-effective, and smooth in operation?

👉 The answer lies in material selection.

Every component, from the track base to the rollers, is carefully designed using specific materials to ensure seamless product movement. Let’s dive into why materials matter and the key properties that define a high-performing system.

Why Material Choice Matters

The material used in a roller track system impacts everything from longevity to performance.

✔ Durability vs. Cost: Finding the right balance is crucial—some materials last longer but come at a higher price.

✔ Load-Bearing Capacity: Different store layouts require varying levels of support. A heavy-duty system may need stronger components.

✔ Smoothness of Operation: A high-quality material minimizes friction, ensuring effortless product flow.

Ignoring these factors can lead to frequent replacements, increasing long-term costs. That’s why selecting the right material is a game-changer for retail spaces.

Key Properties for an Efficient System

Not all materials are created equal. To guarantee smooth performance, a shelf roller track system should have:

✅ Resistance to Wear and Tear – Heavy loads and frequent movement demand tough materials.

✅ Environmental Stability – Exposure to temperature changes, humidity, and chemicals can degrade certain materials faster.

✅ Lightweight but Sturdy Design – A balance between weight and strength improves usability while maintaining durability.

The right combination of these properties ensures a long-lasting, cost-effective, and high-performing shelf solution.

Common Plastics Used in Shelf Roller Tracks

Plastic is widely used in manufacturing roller track components, offering lightweight durability and cost-effectiveness. But not all plastics are the same.

👉 Let’s explore the most commonly used ones and why they dominate the industry.

PET (Polyethylene Terephthalate) – The Industry Favorite

PET is a top choice in the retail industry for a reason.

✔ High Impact Resistance: It withstands repeated use without cracking or deforming.

✔ Eco-Friendly Option: PET is recyclable, making it a sustainable choice.

✔ Lightweight Yet Strong: It reduces system weight while maintaining durability.

This material is ideal for businesses looking for long-lasting, cost-efficient solutions that also support sustainability efforts.

Polycarbonate (PC) – The Heavy-Duty Option

Need something stronger? Polycarbonate might be the answer.

✅ High Strength: PC offers incredible toughness, preventing breakage.

✅ Shatter Resistance: Unlike some other materials, it doesn’t crack under pressure.

✅ Heat Resistance: Perfect for environments where temperature fluctuations occur.

While polycarbonate costs more, it is ideal for heavy-use environments like supermarkets and high-traffic retail spaces.

ABS (Acrylonitrile Butadiene Styrene) – The Budget-Friendly Choice

For those prioritizing cost-effectiveness, ABS is a reliable option.

✔ Good Shock Absorption: Prevents damage from repeated use.

✔ Lightweight Construction: Reduces shipping and installation costs.

✔ Moderate Durability: Best for low to medium-duty applications.

ABS offers affordability, but it may not last as long as other high-end options.

Metal Components in Shelf Roller Tracks

While plastic is common, metal components are sometimes necessary for added strength and longevity.

👉 Let’s explore the two most frequently used metals and their benefits.

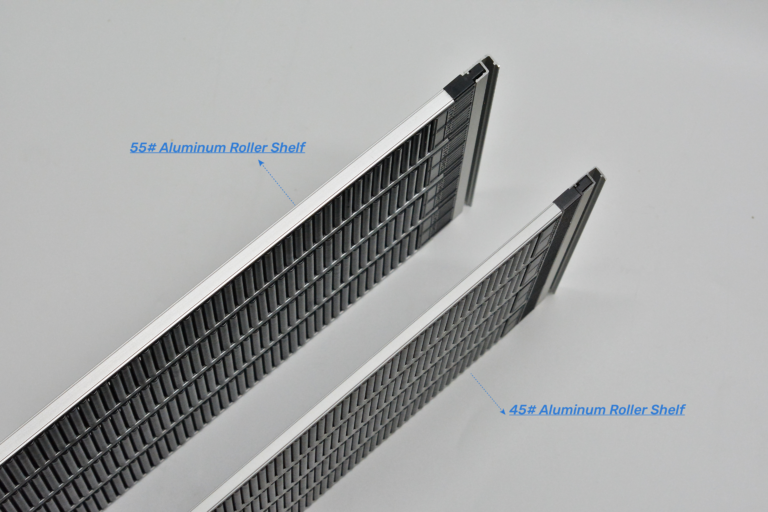

Aluminum – Lightweight Yet Sturdy

Aluminum is a favorite for premium-grade roller track systems.

✅ Corrosion Resistant: Unlike other metals, it doesn’t rust easily.

✅ Lightweight but Strong: Offers durability without adding unnecessary weight.

✅ Aesthetic Appeal: Often used in high-end retail setups due to its sleek finish.

Aluminum provides an excellent balance of strength, weight, and durability, making it a practical choice for many retailers.

Stainless Steel – The Ultimate in Strength

For the toughest applications, stainless steel is unbeatable.

✔ Maximum Load Capacity: Can handle heavy products effortlessly.

✔ Rust and Moisture Resistant: Perfect for humid or refrigerated environments.

✔ Extremely Durable: Lasts longer than most other materials.

Though stainless steel is more expensive, its durability and low maintenance needs make it a long-term investment.

Hybrid Material Solutions – The Best of Both Worlds?

Can combining plastic and metal improve performance? The answer is a resounding yes!

👉 Many manufacturers are now blending these materials to maximize durability while keeping costs in check.

Combining Plastics and Metal for Maximum Efficiency

Some of the best shelf roller track systems use both materials for an optimized experience.

✔ Plastic Rollers, Metal Frames: This setup provides smooth movement while ensuring structural integrity.

✔ Hybrid Tracks: A plastic base with metal reinforcements enhances strength without excessive weight.

✔ Increased Lifespan: Using a mix of materials reduces wear and tear.

Innovation in Material Engineering

Advancements in material science are leading to exciting innovations.

✅ Self-Lubricating Rollers: These reduce friction and extend the life of the system.

✅ Anti-Static Coatings: Prevent dust buildup, keeping shelves clean.

✅ Reinforced Composites: Merging multiple materials to enhance load capacity.

Hybrid solutions are the future of retail shelving, combining cost savings with superior performance.

You got it! Let’s bring it home with the final sections of the post—including a motivating call to action and a snappy, reader-friendly conclusion.

✅ Still using bucket brigades

✅ Still SEO-conscious (no keyword overuse)

✅ Still friendly, practical, and built to convert

Ready to Transform Your Own Store?

So…what’s stopping you?

If your shelves still rely on daily touch-ups and manual restocking, you’re leaving money—and efficiency—on the table. But the good news? You don’t have to overhaul your entire store to start seeing results.

Here’s how to begin:

- Start with a single category

Pick a high-traffic area—like beverages, cosmetics, or snacks—and install shelf automation only there. Monitor the changes. - Use real data

Compare product rotation, restock frequency, and customer flow before and after. You’ll be surprised how quickly the impact shows up. - Talk to a provider who gets retail

You need more than a vendor—you need a team that understands design, production, and fast rollout. That’s where our expertise comes in.

Thinking about scaling this approach?

Why Novaday Makes It Easy

Let’s make things simple.

At Novaday, we specialize in plastic display components designed to help retailers look sharp, stay organized, and sell more. From spring-loaded systems to divider setups and ESL mounts, our team has developed solutions for every store type and shelf style.

Here’s why retailers choose us:

- ✅ In-house R&D for custom design

- ✅ Strong PET injection molding capacity

- ✅ Fast production, fast delivery

- ✅ OEM & ODM services tailored for each market

Looking to become a distributor? We’d love to talk.

Expanding across Europe, North America, and South America, we’re actively searching for regional partners ready to bring next-level retail tech to their networks.

Final Thoughts: Retail Innovation Doesn’t Have to Be Expensive

Still wondering if it’s worth it?

This case study proves that simple upgrades—done right—can unlock serious value. Cleaner displays, smoother operations, happier customers. All without breaking your budget.

Thanks for reading! If this sparked any ideas, or if you want to explore a test run at your store, just reach out. We’re here to help.