Can You Move a Shelf Pusher System After Installation?

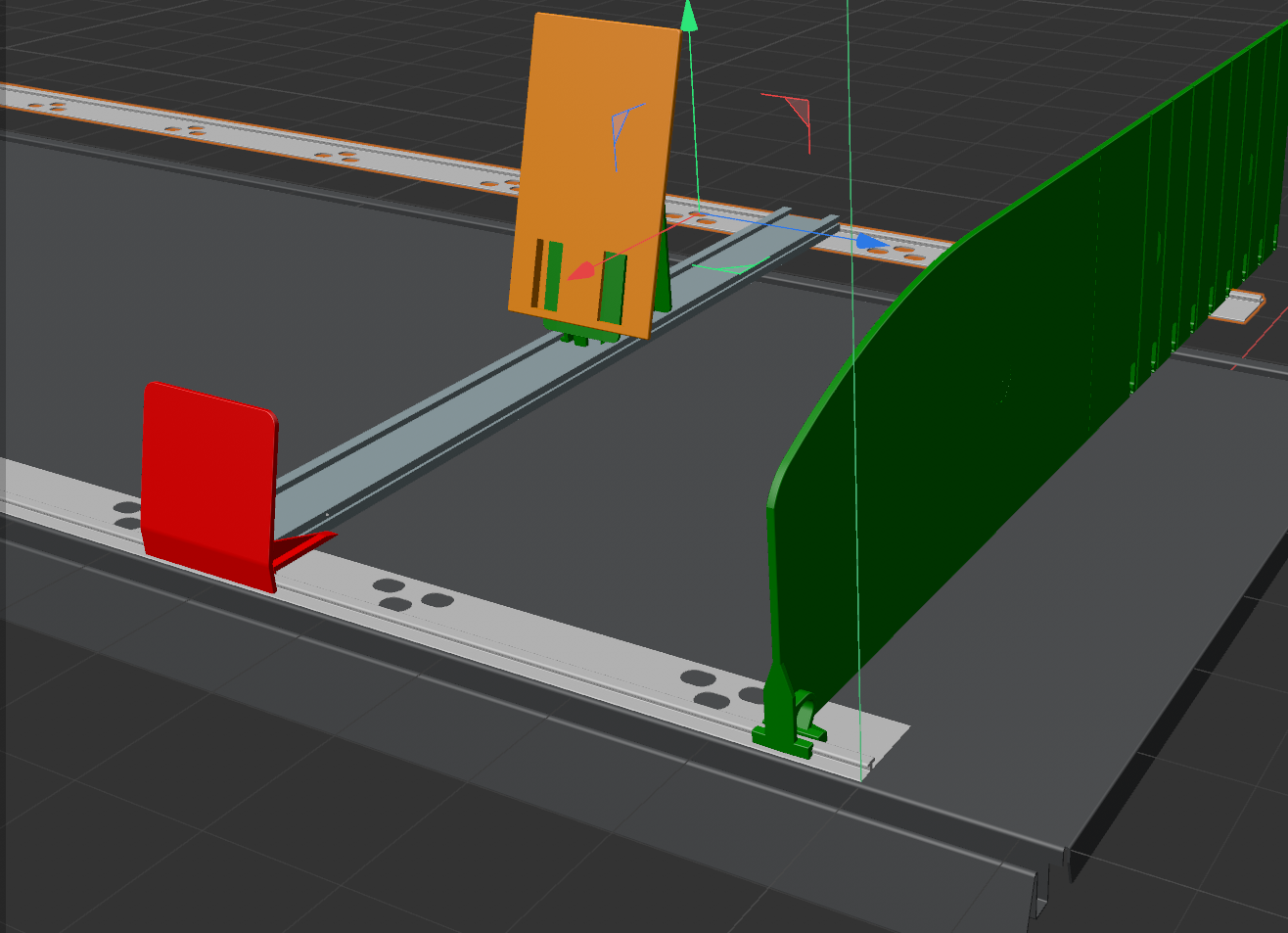

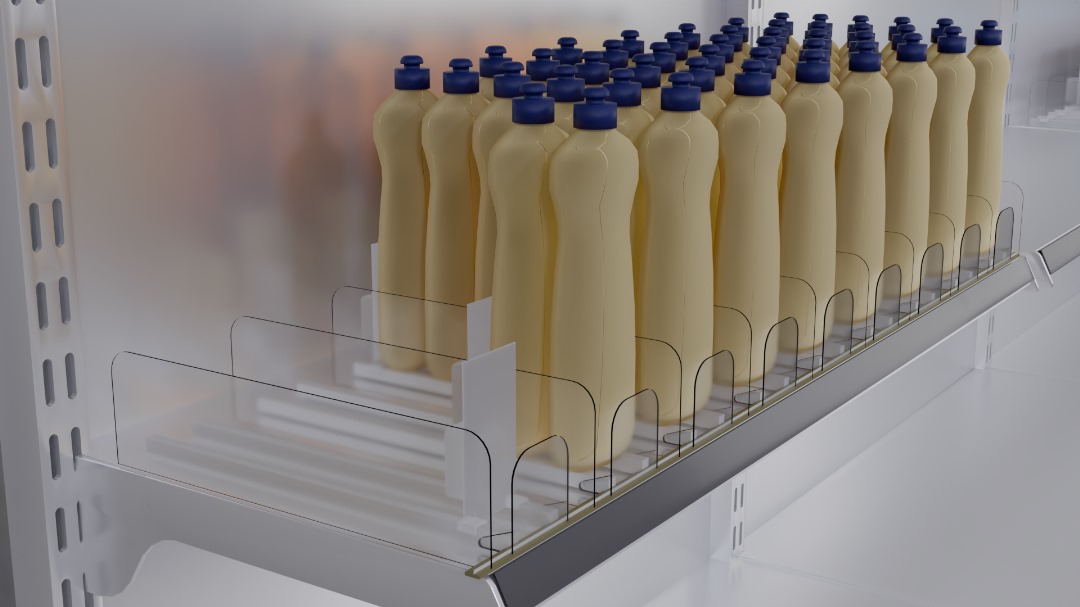

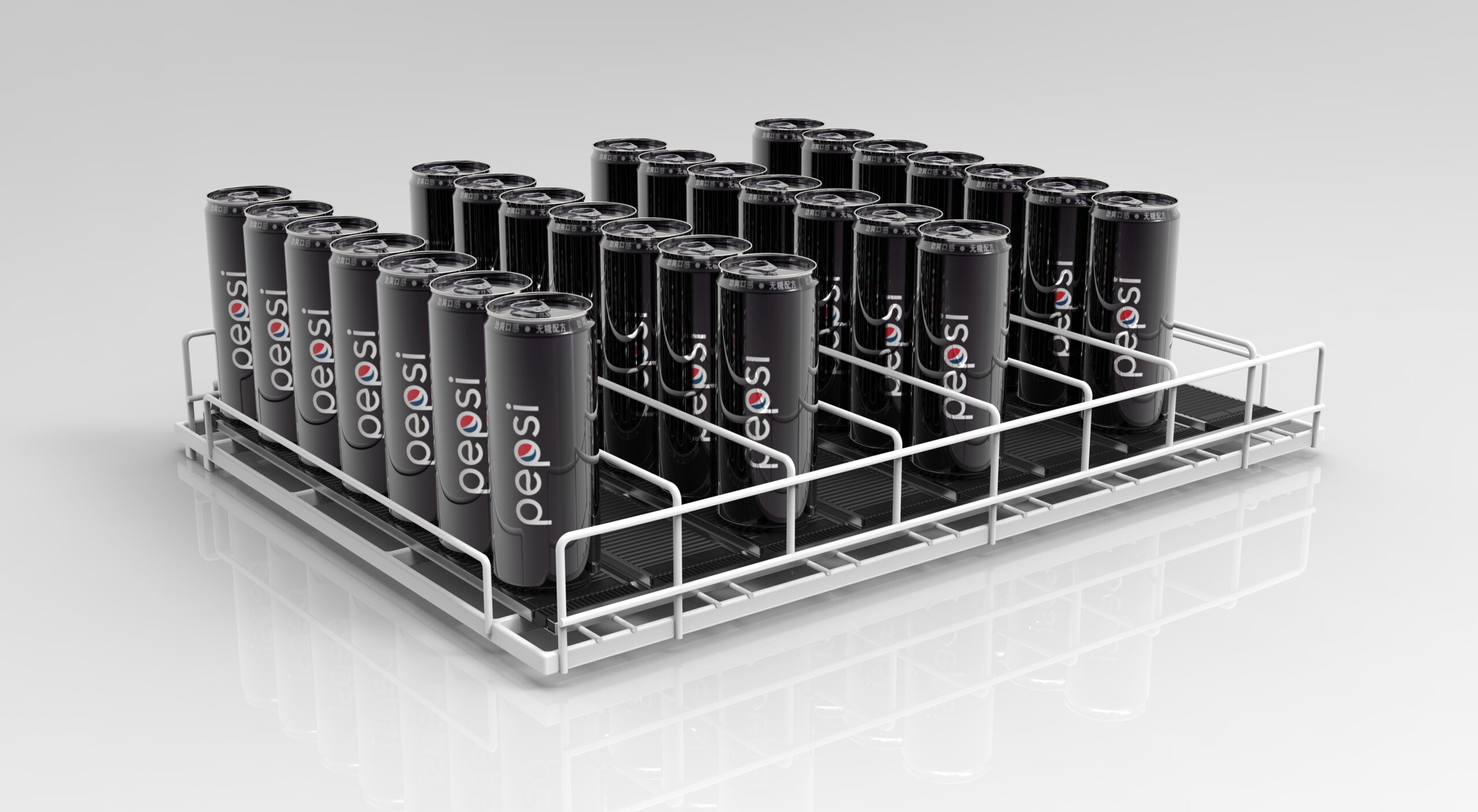

you can move most shelf pusher systems after installation, but it depends on the system’s design, materials, and attachment method. Some units are tool-free and reusable, while others may require careful removal to avoid shelf damage or loss of performance.