WHY PET SHELF DIVIDERS ARE BEST FOR MODERN RETAIL DISPLAYS

Keeping your retail shelves organized isn’t just about aesthetics — it’s about efficiency, shopper experience, and sales performance. And when it comes to shelf dividers, PET (Polyethylene Terephthalate) is dominating for good reason.

In this article, you’ll discover why PET shelf dividers have become the smart standard for modern retail displays — from supermarkets to pharmacies to electronics stores.

Let’s get into the details.

WHAT IS PET — AND WHY SHOULD YOU CARE?

PET, short for Polyethylene Terephthalate, is a high-performance plastic commonly found in packaging, beverage bottles, and now — shelf dividers.

Why is it replacing materials like acrylic and polycarbonate?

Because it’s:

- Lighter

- More eco-friendly

- Easier to mold

- Just as durable — especially when made with injection molding, like we do at Novaday

7 REASONS WHY PET SHELF DIVIDERS OUTPERFORM OTHER OPTIONS

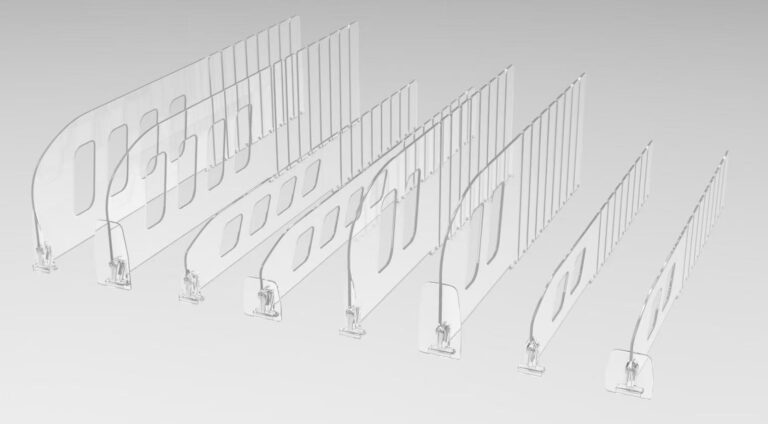

1. Superior Transparency

Shoppers want to see what they’re buying. PET offers crystal-clear visibility that doesn’t yellow over time — keeping your display clean and premium-looking.

2. Lightweight but Strong

PET is light enough for easy handling but strong enough to withstand stocking and cleaning — ideal for fast-paced retail environments.

3. Highly Durable

It flexes under pressure rather than cracking — perfect for cosmetic displays, cold storage, and high-use shelves.

4. Resistant to Moisture and Chemicals

From beverage spills to cleaning sprays, PET holds up. No warping, no hazing, no surface damage.

5. Customizable for Any Shelf Type

Thanks to its injection molding flexibility, PET can be molded to fit any shelf system, including custom tabs, labels, and branding.

6. Eco-Friendly and Recyclable

PET is 100% recyclable and aligns with modern sustainability standards.

7. Cost-Effective at Scale

Mass production using injection molding means you get consistent, high-quality parts without high costs.

HOW PET SHELF DIVIDERS ARE MADE: THE PLASTIC INJECTION ADVANTAGE

Novaday uses plastic injection molding to manufacture PET dividers. This process offers precision, speed, and scalability.

Mold Design

We create custom steel molds based on your shelf specs and branding needs.

PET Material Loading

PET pellets are dried and inserted into injection machines, ensuring optimal clarity and flow.

Injection

Molten PET is injected into the mold cavity under high pressure.

Trimming and QA

Each piece is polished, measured, inspected, and packaged to meet strict quality standards.

At Novaday, all of this happens in-house — so we control quality, reduce lead time, and deliver consistent results.

REAL-WORLD USES FOR PET DIVIDERS

Where do PET dividers shine?

- 🛒 Supermarkets – Neatly organize beverages, dairy, snacks

- 💊 Pharmacies – Display OTC medicines and vitamins with clarity

- 💄 Beauty Stores – Present cosmetics in clean, organized lanes

- 🔌 Electronics Retailers – Keep gadgets and accessories in order

- 🏪 Convenience Stores – Maximize tight spaces with structured layouts

Anywhere there’s clutter, PET dividers bring order.

WHY NOVADAY? YOUR EXPERT IN PET INJECTION MOLDING

Here’s what sets us apart:

✅ PET Injection Specialists – This is our core strength, not a side offering

✅ In-House Mold Development – Get custom sizing, faster prototyping, and full control

✅ OEM/ODM Capabilities – We create to fit your fixture system, branding, and market

✅ Global Delivery – Trusted by clients in Europe, North America, Australia — and expanding into South America

We don’t just sell products — we engineer solutions.

TIME TO UPGRADE YOUR SHELF SYSTEMS?

Still using generic plastic shelf dividers?

PET dividers from Novaday aren’t just cleaner and clearer — they’re built smarter, molded faster, and customized to fit your retail reality.

📩 Get our PET divider catalog today

🛠 Request a quote on custom molding

🧠 Let our engineers help you plan the perfect shelf layout

👉 Novaday — Where PET Meets Precision. Let’s build smarter retail displays.

📌 Hashtags

#PETshelfdividers #InjectionMolding #RetailDisplay #NovadayFactory #CustomRetailSolutions #PlasticManufacturing #StoreEquipmentSupplier