Introduction: The Key to Higher Sales and Less Waste

Retail success depends on efficiency—customers want well-organized shelves, and businesses want to maximize sales while minimizing product waste. But cluttered displays, expired inventory, and constant restocking efforts create challenges that cut into profits.

Here’s where roller track shelving systems change the game. By keeping products front-facing and automatically advancing stock, these systems improve visibility, encourage impulse purchases, and reduce expired goods. Supermarkets, convenience stores, and pharmacies are already seeing the benefits.

This guide will break down how automated shelf tracks optimize store operations, drive revenue, and prevent unnecessary losses. Whether you run a grocery store or manage a retail chain, you’ll discover how this simple upgrade can transform your business.

The Science Behind Shelf Roller Tracks

Let’s start with the basics.

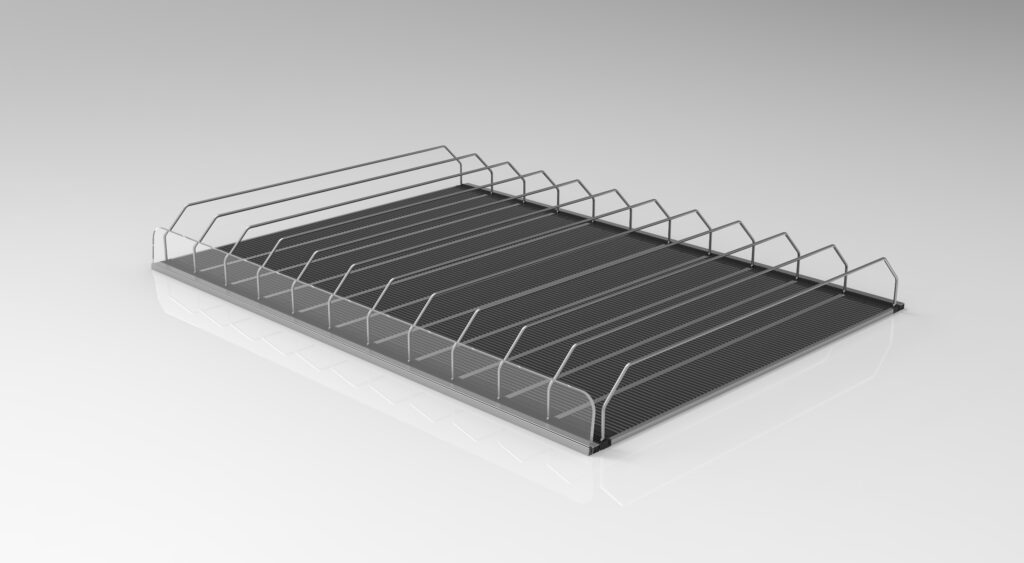

A roller track shelving system is designed to keep products moving forward, ensuring they stay visible and easily accessible. Instead of relying on employees to constantly reorganize shelves, this system uses gravity and low-friction tracks to do the work automatically.

Retailers love this innovation because it saves time, enhances product visibility, and improves the shopping experience. But how does it actually work?

How Gravity-Driven Shelving Works

Ever noticed how drinks in a cooler always seem to slide forward? That’s gravity-fed shelving in action!

🔹 Inclined tracks: Shelves are slightly tilted so products move toward the front naturally.

🔹 Roller or glide sheets: Reduce friction, allowing smooth movement.

🔹 Dividers: Keep products in place and prevent misalignment.

By automating front-facing displays, businesses ensure that customers always see a full, well-organized selection without extra labor.

The Psychology of Front-Facing Products

Did you know that shelf placement affects buying behavior?

👀 Eye-level placement sells more: Customers are more likely to grab what they see first.

🛒 Clutter kills sales: Messy shelves overwhelm buyers and reduce impulse purchases.

📌 Neat displays build trust: Well-organized products create a premium shopping experience.

By using roller tracks, retailers keep items front and center, maximizing visibility and increasing sales.

Shelf Roller Tracks vs. Traditional Shelving

Not all shelves are created equal!

✔ Traditional shelving: Requires constant restocking and manual front-facing.

✔ Roller track systems: Products automatically move forward, reducing labor.

✔ Better stock rotation: No more forgotten items hidden at the back of shelves.

Retailers using automated shelf systems see improved efficiency, better sales, and fewer expired products.

How Shelf Roller Tracks Boost Sales

Here’s the big question—how does this system actually increase revenue?

By keeping products visible, accessible, and organized, businesses experience higher sales and better customer satisfaction. Let’s break it down.

Maximizing Product Exposure

Ever noticed how some products seem to sell faster than others? That’s not by accident!

🌟 Better shelf positioning: Items are always front-facing, making them easier to find.

🚀 Increased customer engagement: Shoppers are more likely to grab products they see immediately.

🔄 Consistent restocking efficiency: Employees spend less time fixing displays and more time assisting customers.

The more visible an item is, the more likely it is to sell!

Encouraging Impulse Buying

Impulse purchases account for a huge portion of retail sales. But if products are hidden or hard to reach, customers simply move on.

🛍 Grab-and-go mentality: Shoppers are more likely to add items to their carts when products are neatly displayed.

🎯 Strategic product placement: Roller tracks make it easier to highlight promotional or seasonal goods.

📈 Faster decision-making: Clear, organized shelves create a stress-free shopping experience, leading to quicker purchases.

By optimizing shelf organization, retailers create an environment where customers spend more.

Faster Restocking Means More Sales

Time is money—especially in retail!

⏳ Less time spent adjusting shelves – Employees don’t have to constantly move products forward.

📦 Stock rotation improves automatically – Older items are always at the front.

💡 More time for customer service – Staff can focus on assisting shoppers instead of fixing shelves.

A well-managed shelf system means products are always available, leading to better sales performance.

The Role of Shelf Roller Tracks in Waste Reduction

Sales are important, but so is reducing unnecessary waste.

Expired products, damaged goods, and inefficient stock rotation can lead to significant losses. Luckily, automated shelving systems help retailers cut down on waste and improve sustainability.

First-In, First-Out (FIFO) Stock Rotation

Food retailers know the struggle—items at the back of the shelf often expire before they’re sold. That’s a big problem!

🔹 How FIFO works: The first items placed on the shelf are the first to be sold.

🔹 How roller tracks help: Older stock stays at the front, ensuring better inventory turnover.

🔹 The result: Reduced food waste and lower financial losses.

This method is especially crucial for supermarkets and pharmacies that deal with expiration dates.

Minimizing Overstock and Stock Loss

Overordering leads to cluttered shelves and wasted products. Here’s how shelf optimization helps:

✔ Better inventory visibility: Employees can see stock levels at a glance.

✔ Easier restocking: No more misplaced or forgotten products.

✔ Less markdown waste: Items sell before they need to be discounted.

By improving stock flow, retailers can reduce unnecessary losses and keep profits high.

Cutting Down on Labor Waste

Wasted labor means wasted money. Automated shelf systems help businesses:

🔄 Reduce manual front-facing efforts – Employees no longer have to rearrange shelves constantly.

⏳ Save time on inventory checks – A quick glance tells staff what needs restocking.

💰 Lower overall labor costs – Less time spent adjusting shelves means more time for revenue-generating tasks.

With better efficiency, businesses save money while reducing unnecessary work.

Industries That Benefit Most from Roller Track Shelving

Not all industries operate the same way—but many can benefit from this technology!

Supermarkets and Grocery Stores

Freshness matters. Supermarkets need smart shelving solutions to ensure food stays fresh and stocked properly.

🥦 Better organization in produce, dairy, and beverages.

🍞 Minimized food waste with automatic stock rotation.

🛒 Faster restocking in high-traffic aisles.

Convenience Stores and Small Retailers

Limited space? No problem. Small stores need efficient shelf management to make the most of their layout.

📏 Optimized shelf space for grab-and-go items.

💼 Less time spent adjusting displays, more time helping customers.

🔄 Better product turnover for impulse buys.

Pharmacies and Cosmetic Retailers

Pharmacies and beauty stores deal with small, high-value products that need to be well-organized.

💊 Ensuring first-to-expire medications stay at the front.

💄 Keeping beauty products neatly displayed for easy access.

🔎 Reducing misplaced items and improving stock control.

From food to beauty to pharmaceuticals, roller track shelving keeps businesses running smoothly.

Choosing the Right Shelf Roller Track System

Ready to upgrade? Not all systems are created equal.

Understanding Different Track Types

📌 Fixed tracks: Best for stores with consistent inventory.

🔄 Adjustable tracks: Ideal for businesses that change product layouts often.

💡 Hybrid solutions: A mix of both for added flexibility.

Customization for Business Needs

Not every business has the same shelving requirements. Custom features include:

⚙ Modular dividers for different product sizes.

📲 Integration with digital price tags.

🔧 Different materials for durability.

Budget Considerations for Retailers

💰 Upfront investment vs. long-term savings.

📉 ROI comparison with traditional shelving.

📦 Bulk purchasing options for cost-effectiveness.

Investing in better shelf management pays off quickly!

Common Challenges and How to Overcome Them

Let’s be honest—no system is perfect!

While automated shelf tracks make retail operations smoother, a few common challenges can arise. The good news? Most of these issues have easy solutions that keep your shelves running efficiently.

Products Getting Stuck or Jamming

Ever noticed items refusing to slide forward? This is one of the most common problems in shelf management.

🔹 What causes it?

- Overloaded shelves that exceed weight limits.

- Poor alignment during installation.

- Dirt and debris slowing down movement.

🔧 How to fix it?

✔ Ensure weight distribution is even.

✔ Regularly clean tracks to remove dust buildup.

✔ Use high-quality, low-friction rollers for smoother movement.

A simple maintenance routine ensures products slide forward effortlessly!

Choosing the Right Angle for Optimal Movement

Gravity does the work—but only if the shelves are set up correctly!

🔹 Common mistakes:

- Shelves that are too flat don’t create enough movement.

- Shelves that are too steep can cause items to slide too fast or fall over.

🔧 How to fix it?

✔ Test different angles before full installation.

✔ Adjust the tilt based on product weight.

✔ Use dividers to keep items securely in place.

Finding the perfect balance keeps your display neat and functional!

Keeping Shelves Clean and Functional

Dirt and dust can slow product movement—leading to stock rotation issues.

🔹 Cleaning tips:

✔ Wipe tracks regularly with a dry cloth.

✔ Avoid using harsh chemicals that may damage rollers.

✔ Inspect shelves monthly for signs of wear and tear.

A clean shelving system is a high-performing system!

The Future of Shelf Roller Track Technology

Retail shelving is evolving fast!

New innovations are making automated shelf systems more efficient, high-tech, and eco-friendly. Here’s what’s coming next.

Smart Shelf Systems and AI Integration

Imagine knowing exactly when to restock—before a product runs out!

🚀 What’s new?

- AI-powered sensors track real-time inventory levels.

- Automated restocking alerts ensure products never go out of stock.

- Data-driven analytics help retailers optimize stock placement.

💡 Why it matters?

✔ Prevents out-of-stock issues.

✔ Reduces product waste through smarter stock control.

✔ Saves employees time by automating inventory checks.

The future of shelving is smart, connected, and efficient!

Sustainable and Eco-Friendly Materials

Retailers are moving toward greener solutions.

♻️ What’s changing?

- Use of recycled materials in shelving components.

- Reduction of plastic waste in shelving accessories.

- Energy-efficient automation to lower carbon footprints.

💡 Why go green?

✔ Meets environmental standards and regulations.

✔ Attracts eco-conscious shoppers.

✔ Reduces long-term operational costs.

Sustainability is no longer optional—it’s the future of retail!

Digital Price Tag Integration

Say goodbye to manual price updates!

📲 How it works:

- Electronic shelf labels sync with inventory systems.

- Prices update automatically across all store locations.

- Dynamic pricing strategies become easier to implement.

💡 Retailers love it because:

✔ No more printing and replacing paper price tags.

✔ Reduces pricing errors and improves accuracy.

✔ Saves time and streamlines operations.

The combination of automated shelves and digital pricing is transforming modern retail!

Case Studies – Real Business Success with Roller Tracks

Nothing beats real-world results!

Businesses across different industries are already seeing massive benefits from shelf automation.

A Supermarket Chain Reducing Expired Inventory by 40%

🛒 The problem:

- Overstocked items were getting pushed to the back of shelves.

- Expired products were frequently found during audits.

- Employees spent too much time reorganizing shelves.

🔥 The solution:

- Implemented automated shelf tracks for FIFO stock rotation.

- Adjusted shelf angles to ensure smooth product movement.

- Trained staff on optimizing restocking practices.

💡 The results:

✔ 40% reduction in expired inventory.

✔ Faster product turnover and fewer markdowns.

✔ Increased efficiency in stock audits.

This simple upgrade cut waste and increased profits!

A Convenience Store Boosting Impulse Sales by 25%

🏪 The challenge:

- Cluttered snack and beverage shelves made it hard for customers to find products.

- Employees spent too much time manually front-facing items.

🚀 The fix:

- Installed roller tracks to ensure drinks and snacks stayed neatly front-facing.

- Placed high-margin impulse items in prime locations.

💡 The impact?

✔ 25% increase in impulse purchases.

✔ Less labor required for shelf organization.

✔ Improved customer satisfaction.

Small adjustments made a big difference in sales!

A Pharmacy Cutting Down Manual Shelf Adjustments by 50%

💊 The issue:

- Small pharmaceutical products often got pushed to the back of shelves.

- Employees spent too much time adjusting shelves for optimal visibility.

🔧 The upgrade:

- Introduced roller track shelving for better stock organization.

- Used adjustable dividers to keep different products neatly arranged.

💡 The win:

✔ 50% reduction in time spent reorganizing shelves.

✔ Improved inventory accuracy.

✔ Faster access to high-demand medical products.

Efficiency improvements saved both time and money!

How to Implement Shelf Roller Tracks in Your Business

Ready to take the next step? Here’s how to successfully integrate these systems into your store.

Finding the Right Supplier

Not all shelving solutions are created equal!

🔎 What to look for:

✔ A proven track record in the industry.

✔ Customization options for different shelf sizes.

✔ Reliable customer support for installation and maintenance.

💡 Pro tip: Work with manufacturers that offer OEM and ODM services for a tailored solution!

Installation Tips for Maximum Efficiency

Don’t worry—setup is easier than you think!

🔹 Step-by-step process:

1️⃣ Measure shelves and determine the best track angle.

2️⃣ Choose the right track type for your products.

3️⃣ Secure the system in place and test movement.

4️⃣ Train employees on usage and maintenance.

💡 Avoid common mistakes:

❌ Skipping the leveling process.

❌ Overloading shelves with heavy items.

❌ Ignoring regular maintenance.

A well-installed system delivers long-term efficiency!

Getting the Best ROI from Your Investment

Thinking long-term? Here’s how to maximize your returns.

📈 Track performance metrics:

✔ Monitor sales increases after installation.

✔ Measure waste reduction and expiration rates.

✔ Analyze labor cost savings over time.

💡 Expand when ready:

✔ Start with high-traffic sections, then scale store-wide.

✔ Combine with digital price tags for full optimization.

✔ Adjust based on customer shopping patterns.

Investing in better shelving technology pays off in more ways than one!

FAQs About Shelf Roller Track Systems

Still have questions? Let’s clear them up!

Do Shelf Roller Tracks Work for All Types of Products?

🔹 Best suited for:

✔ Packaged food and beverages.

✔ Health and beauty products.

✔ Small boxed items and pharmaceuticals.

🔹 Limitations:

- Not ideal for oversized or oddly shaped items.

- Weight limits vary based on track type.

Are They Easy to Maintain?

✔ Yes! Basic maintenance includes:

- Weekly cleaning of tracks.

- Routine checks for misalignment.

- Replacing worn-out rollers as needed.

How Quickly Do Retailers See Results?

📊 Most businesses notice improvements within weeks!

✔ Faster restocking.

✔ Better product rotation.

✔ Higher sales from better visibility.

Conclusion

Retail success depends on efficiency and organization—and automated shelf systems deliver both.

By improving product visibility, stock rotation, and labor efficiency, businesses increase sales while reducing waste.

Ready to upgrade? The right shelving solution can transform your store today!